Created in 2012, the SNCF* technical center of French region Charentes-Périgord is one of the ten industrial centres directed by the “Equipment” entity of the SNCF Mobility operator, itself part of the SNCF group, one of the leading transport and logistics groups in Europe. Supported by 750 dedicated workers, it is responsible for the Equipment Department – which means the design, transformation and technical maintenance of railway rolling stock.

The project, carried out by the technical centre on its site of Périgueux, concerned the refit of its obsolete electrical cabinets for control units. The technical centre aimed to achieve energy savings on fluids, including gas, and to effectively monitor the temperature in its workshops in order to standardise thresholds.

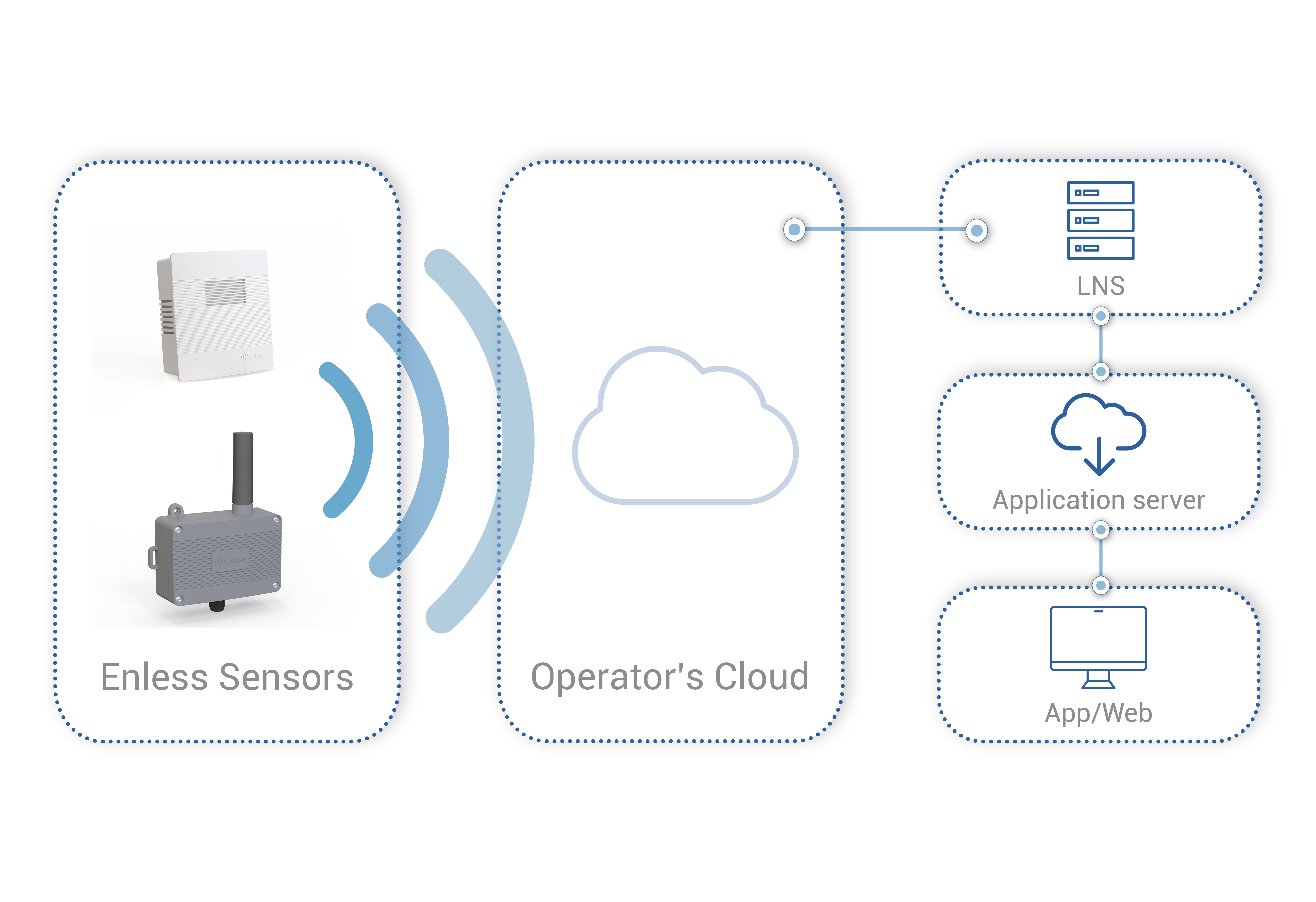

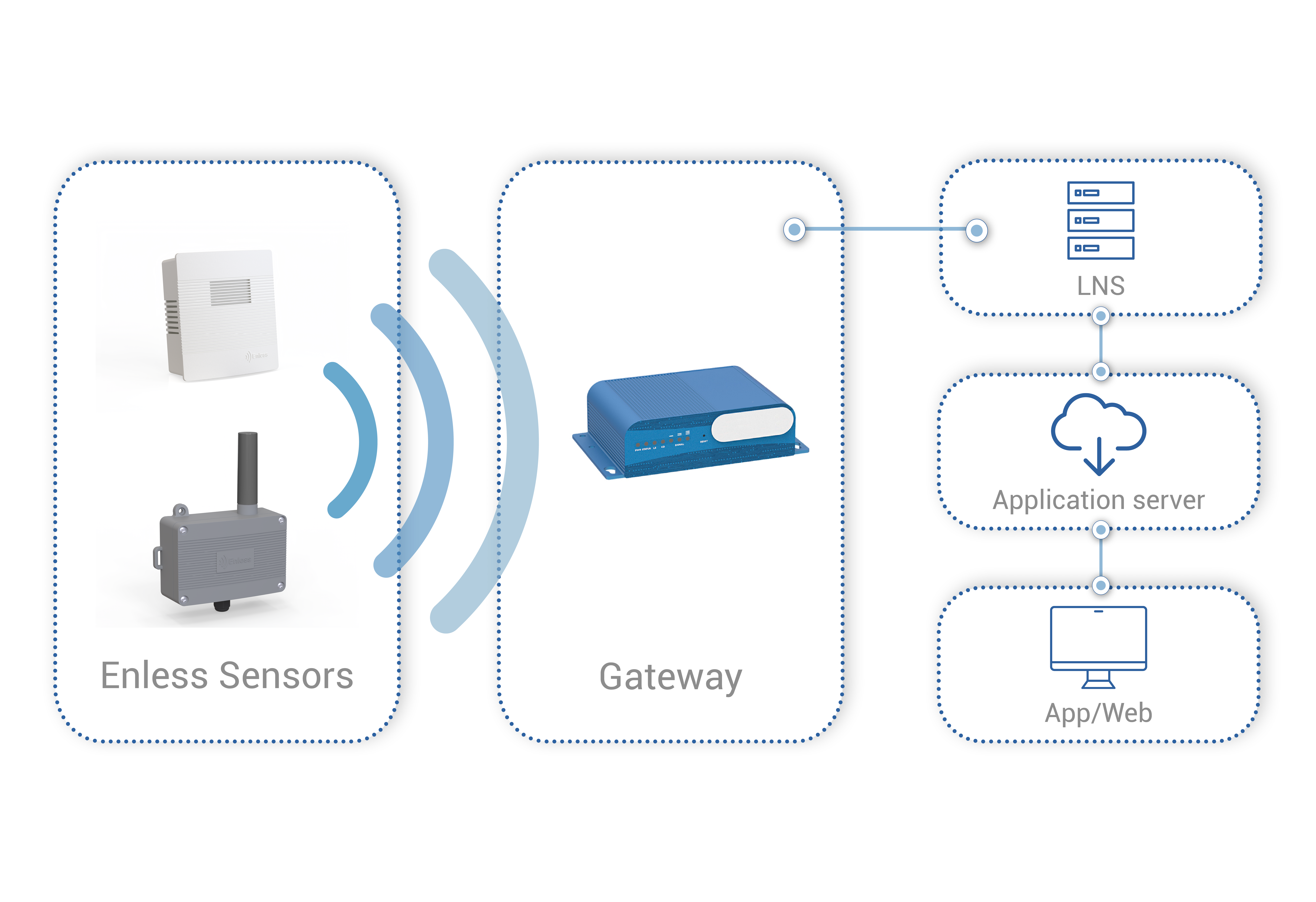

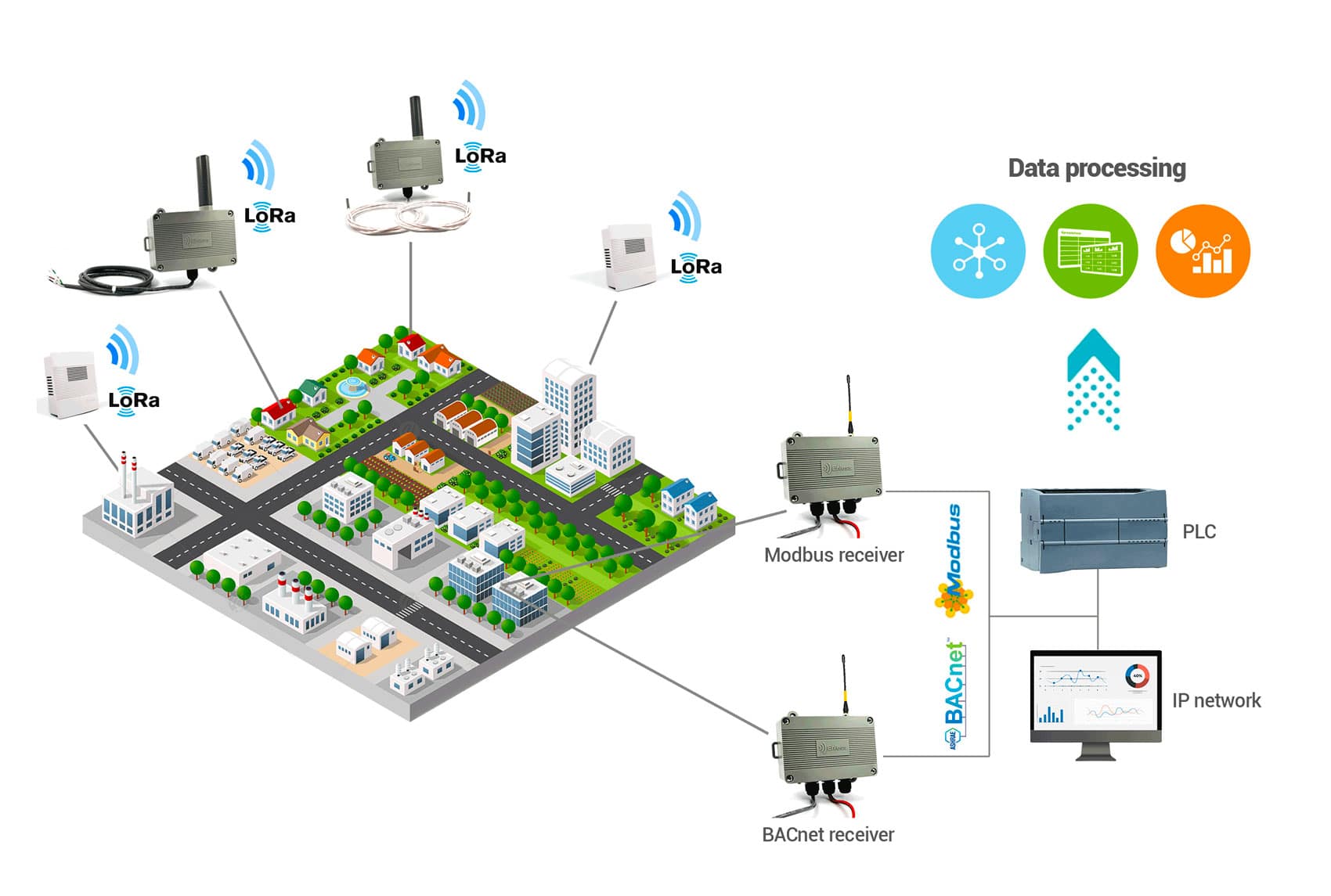

To enable this project, sixty-five Enless Wireless Wireless M-Bus 169 MHz temperature transmitters were installed in the production areas of the technical centre, paired with receivers. Contact transmitters were also set to control the position of the outward access curtains. The gas delivery meters of the site were also connected to Enless certified Atex metering transmitters to monitor the gas consumption of the technical centre.

An internal supervision system (visualisation platform), connected to the remote terminal units that collect the data from the Enless Wireless sensors, enables monitoring of all facilities in real time.

This global solution implemented on behalf of the production area of the site has already enabled the achievement of 25% savings on the gas for 2018 compared to 2017. SNCF Mobility operator will shortly organise a refit for the rest of its workshops.

*French transport operator

Click on the icons below to post this article on social networks >>>