A question of size

Certain industrial sectors require heightened monitoring of their energy consumptions which given their core activity, constitute a strategic challenge. This is true for the food industry in general and more specifically for the manufacture of syrups that requires considerable quantities of water.

For the production of the top-of-the-line Monin brand syrups, this family run business, established in Bourges in 2015, consumes on average, 4600m3 of water per month (for the overall operation of the site and specifically for the production of syrups), thus producing an impressive, twelve thousand bottles per hour and twenty-five million bottles per year.

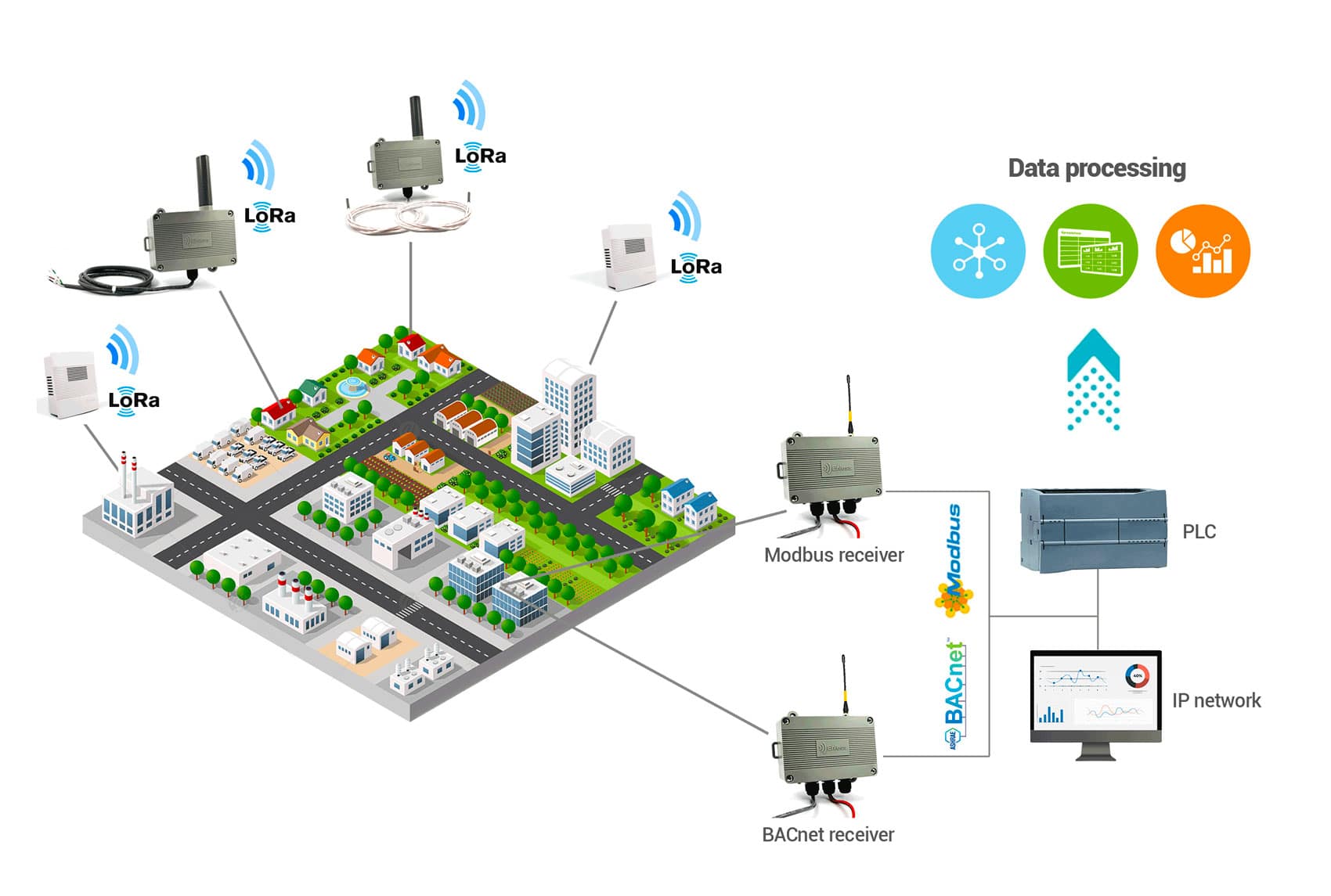

In total, there are nearly 20,000 square metres of industrial space dedicated to the manufacture of syrups and these are distributed over the industrial zone of Bourges, in the Centre-Val de Loire region of France, on the sites of Saint-Florent-sur-Cher and La Chapelle-Saint-Ursin.

Read more : Smart metering

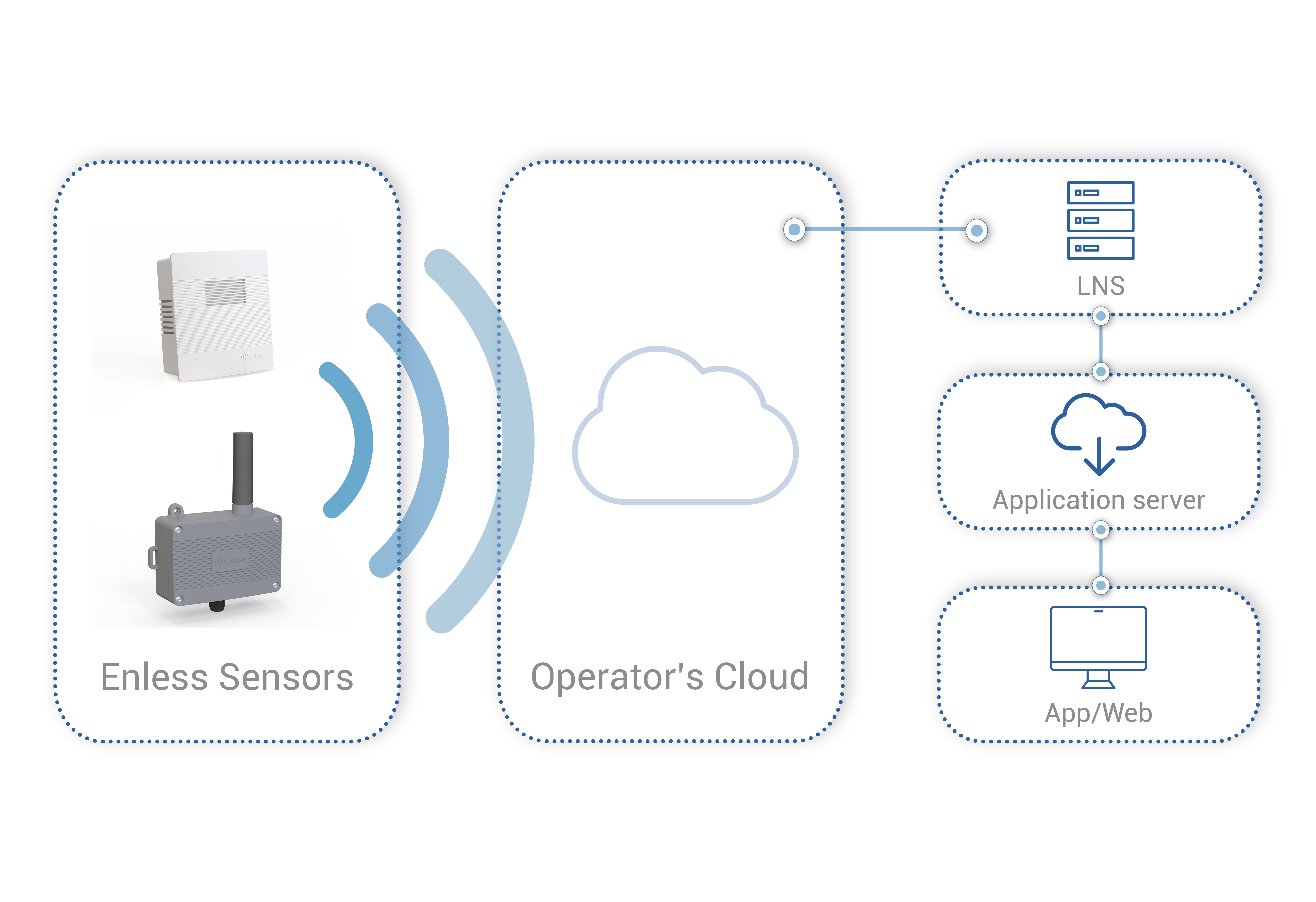

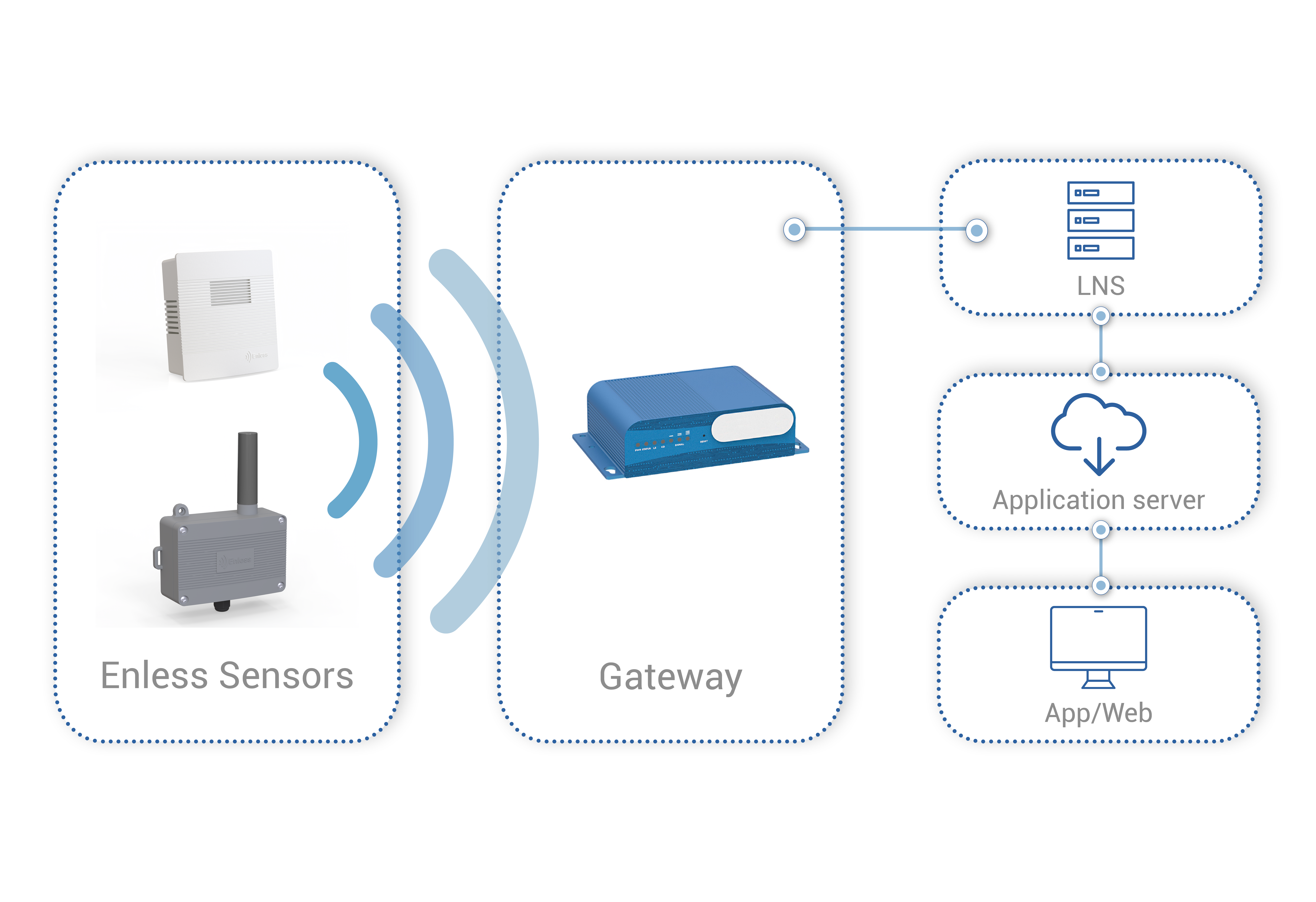

BSE, Hervé Thermique and Enless have collaborated on the establishment of a smart, real-time water metering system in the Monin plants

Being concerned about controlling the energy and fluids consumption, the Monin plant in Bourges, being a major consumer of water, wished to establish an automated monitoring system for its water consumption on its industrial site, so as to have a handle on its bills, being able to detect possible anomalies/breakdowns such as leaks in its network and to avoid their technical personnel having to perform the manual reading of meters situated in a pit.

This large scale project was taken charge of by the members of the Energy and Services cluster of the group Hervé, BSE and Hervé Thermique, specialised respectively in energy efficiency (from auditing to the execution of works and performance monitoring) and in air treatment engineering (HVAC, connected objects, etc.).

In the framework of its development, the Hervé group deploys energy monitoring solutions associated with connected maintenance by offering its customers, A to Z assistance, with commitments to results.

Practically speaking, the customer wished to relay the data from the water meters situated in pits and in the sprinkler system (permanent automatic water-based fire extinguishing installation), to the more than 100m of main buildings of the plant. The specificities of the site did not allow a wired system to be installed which would have taken longer and have been more costly to put in place. The other essential prerequisite was to base the systems on a long range, resistant communication mode as the site presented buildings in steelwork and concrete.

Thus, since the month of May 2019, several Enless Wireless Pulse transmitters communicating in radio mode over the 169 MHz frequency band (M-Bus Wireless mode) paired with an Enless Wireless receiver and two repeaters, have been installed on the site (in the town of La Chapelle-Saint-Ursin).

Indeed, the Wireless M-Bus 169 MHz technology that makes communication possible up to an open field distance of 2.5 km, appeared as the most suitable for the monitoring of extended buildings as was the case for these industrial sites.

Julien Guillon, energy efficiency engineer at BSE and Gilles Pallier, maintenance technician at Hervé Thermique tells of the ease of implementing the transmitters on their customer’s site: “In addition to supplying quality products, the video tutorials for assisting with the Enless Wireless installation are really practical! We configured the periodicity of the transmitters to allows us to relay the information every 5 minutes and thus to have a fine analysis of the data”.

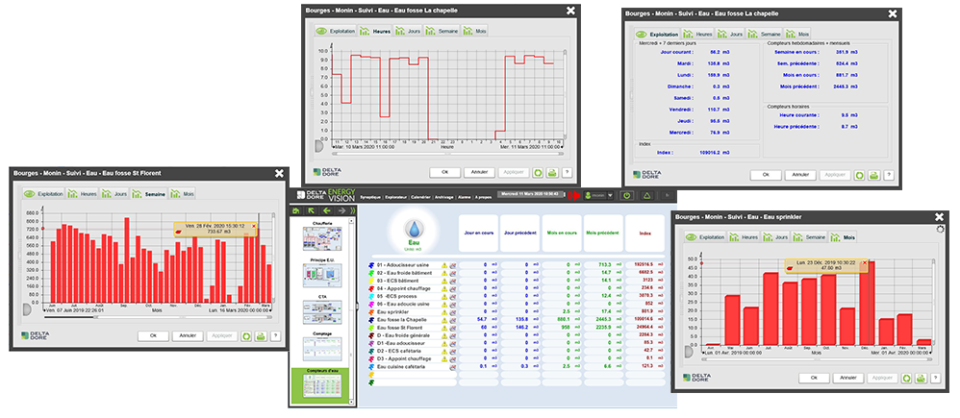

Once captured then sent by the Enless Wireless transmitters with a frequency preconfigured by the BSE/ Hervé Thermique teams, the water consumption data is relayed to the CMS of the plant site. They are combined via the Energyvision Delta Dore PLC and coupled to data from a dozen other meters on the site, previously connected by wires.

A team of technicians on site monitor the formatted data in real time.

What are the results?

“The Enless Wireless remote reading solutions have allowed our customer to go beyond manual readings performed in the past, by technical teams on meters that were sometimes located in a pit which was not at all a very pleasant job! The technicians had to go down into the pits which required special equipment and organisation”. Julien Guillon, Energy Efficiency Engineer at BSE.

Apart from requiring fewer personnel for the manual readings of the meters performed in the past, installing the solution has provided greater accuracy for the data read and analysed allowing closer predictions to be made of expenses related to the site’s water consumption.

Click on the icons below to post this article on social networks >>>